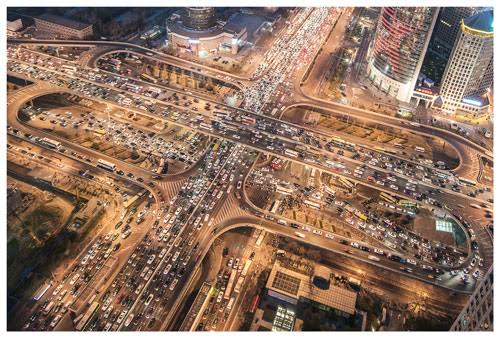

China may be the only country to come close to offering infinite automotive opportunities. It’s quite simple really, by 2020, China is expected to have more than 200 million registered vehicles.And that’s only a tiny fraction of the country’s total population of 1.4 billion people so there’s still a lot of room for growth. China also has its fair share of logistics challenges for automotive manufacturers. But the right logistics provider can help smooth out those challenges.

Top logistics challenges faced by automotive manufacturers in China

All supply chains—no matter the industry face challenges that affect the two most important aspects of the process: time and money. The top challenges of automotive manufacturers in China can affect both:

Geography challenges

As part of China’s efforts to improve rural infrastructure, the government offers many incentives for automotive manufacturers to move operations to rural provinces. While lucrative, the incentives don’t always make up for the added challengesof operating in these outer provinces.

These manufacturers often find China’s vast physical geography to be a significant barrier. The sheer amount of land to traverse to reach a port city combined with limited infrastructure can both slow down transportation and make it more costly.

Regulatory challenges

Also, despite China’s national government’s ongoing efforts to make regulations less bureaucratic and cumbersome, national requirements and municipal regulations may differ greatly. This can cut into efficiency efforts and tack on expenses.

From a technical perspective, the Chinese government has already readily opened key databases so that logistics providers and manufacturers can share information and expedite customs processes. Over time, similar regulatory inefficiencies should also be improved.

Understanding what “the right logistics provider†means for China

Understanding what “the right logistics provider†means for China

There are few logistics providers that have the ability to serve both Tier 1 coastal cities and interior China equally. Regional providers often have difficulties serving both markets—and face visibility challenges as well. A global logistics provider will be better equipped to meet the needs of an automobile manufacturer in China, but the right logistics provider can offer much more.

Full range of services based on needs

Even in the just in time (JIT) environment that often occurs in the automotive industry, executing global transportation functions is the most basic requirement of any logistics provider. As was noted earlier, very few logistics providers offer a full range of services truck, rail, ocean, and air within China and beyond. But this is absolutely what’s needed for automotive manufacturers.

A qualified global logistics provider should offer reliable global services beyond China’s borders. After all, it’s possible to need accommodations for changes in suppliers and distribution channels outside of China too.

Specialized knowledge and global reach

Specialized knowledge and global reach

Automotive supply chains are different from other industries. The right logistics provider will be able to go beyond the basics of transportation and provide other skills and knowledge specific to the industry and the business.

Often this can be filled with the role of an assigned account manager who can act as the point of contact for day to day operations and as a collaboratoron continuous improvement efforts. In this role, they become part of the company’s global logistics team. They can also understand and watch industry trends and regulations around the world to keep the company informed on changes that can impact the supply chain.

End to end solutions

A logistics provider’s capabilities should support the entire supply chainprocess from inbound parts for production to JIT outbound delivery for key customers. A logistics provider with proven automotive capabilities and a worldwide distribution network will have the visibility to create custom end to end solutions that can resolve new and unexpected challenges faced by the ever-changing automotive industry.

Global technology systems

Transportation management systems (TMS) can help with planning, execution, tracking, and overall visibility. A capable TMS can scale with a company’s growth plans, and serve both China and other regions.

Combining a logistics provider with a global TMS, can help enforce consistent processes, shareinformation across the country, and provide visibility to shipments in transit. It can also help ensure clear and efficient communication between organizations.

Adaptability to change

Any logistics provider should be prepared withcontingency plans and recommendations based on how potential industry and market changesmight affect the supply chain from simple weather disruptions to significant regulation changes. The provider should also be able to forecast and help prepare for larger, strategic changes like emerging technology trends and the growing popularity of ecommerce.

A logistics provider success story

A manufacturer produces radiators and condensers ina Tier 1 city in China, but they have customers around the world in theautomotive aftersales market. They found their logistics provider wasextremely helpful in three important ways:

1. Rates

In the beginning, this company had only small, irregularshipments. They sought out carriers only as they needed them, usingthe spot or transactional market. However, as the company grewover time, their volumes became steadier.With predictable, weeklyshipments, this company’s freight was far more attractive to carrierslooking for regular business. The logistics provider helped themnegotiate annual carrier contracts at more competitive pricing.

2. Global logistics coordination

2. Global logistics coordination

Once this company’s sales office inTaiwan sold to U.S. customers, they shipped the order to their factory inChina. The logistics provider managed the orders and communications.Further, proper coordination of timing for pickups, customs clearance, and with carriers in China and the U.S. ensured the product wasdelivered on time.

3. Change management

When the port strikes occurred on the U.S.West Coast in 2014 and 2015, on time deliveries were threatened.The provider rerouted shipments and arranged for over the roadcarriers to pick up the product at a port in Canada to facilitate deliverythat still met the U.S. customer’s requirements.

Over fifteen years, this company developed a strong relationship with its logistics provider as they exported to the United States and Europe. The relationship is based on highly competitive rates, full customs regulation and compliance knowledge, and responsiveness.

Today, the company has two factories in China. They’ve grown from being an exporter to merging with their original buyer in the United States. Although their new high-security facility in the original location is five times the original size, the company still works with its trusted global logistics provider.

Controlling the supply chain in China

Controlling the supply chain in China

Ultimately, automotive companies need strategic business relationships with the right logistics providers to extend and enhance their own logistics expertise in China. This brings better control, consistency, quality, and cost effectiveness to automotive manufacturing supply chains.

Shawn Chen, Director of Sales, Asia, for C.H. Robinson

Shawn Chen is the recently promoted corporate Director of Sales, Asia, for C.H. Robinson. He is responsible for development, training, and hiring for C.H. Robinson’s client acquisition and retention process. In addition, Shawn is directly responsible for global client relationship management, ensuring the highest level of customer service for our global partners. In his 13+ year tenure at C.H. Robinson, Shawn has worked in various locations around the world, leading C.H. Robinson’s sales and business development efforts.

With stints in various regions of the United States, South America, Hong Kong, and most recently Singapore, Shawn brings a wealth of knowledge to matters of consultative supply chain analysis, change management, free trade programs, and organizational team development. Prior to C.H. Robinson, Shawn spent time in the heavy industrial sector.

He is a graduate of Juniata College, a liberal arts university in Pennsylvania, USA, with a bachelor’s degree in international business and Spanish language studies.

About C.H. Robinson

At C.H. Robinson, we believe in accelerating global trade to seamlessly deliver the products and goods that drive the world’s economy. Using the strengths of our knowledgeable people, proven processes and global technology, we help our customers work smarter, not harder. As one of the world’s largest third party logistics providers (3PL), we provide a broad portfolio of logistics services, fresh produce sourcing and managed services for more than 113,000 customers and 71,000 contract carriers through our integrated network of 280 offices and more than 14,000 employees. In addition, the company, our Foundation and our employees contribute millions of dollars annually to a variety of organizations. Headquartered in Eden Prairie, Minnesota, C.H. Robinson (CHRW) has been publicly traded on the NASDAQ since 1997.

For more information, visit http://www.chrobinson.com

or view our company video https://www.chrobinson.com/en/us/About-Us/